By Jack Ryan

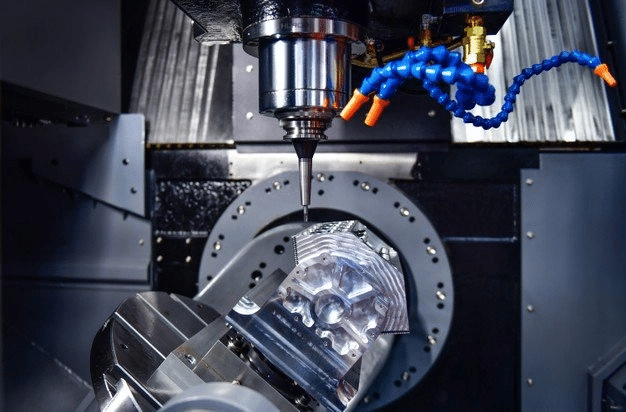

In modern CNC manufacturing, consistency is not optional. Every machined part must meet dimensional, geometric, and functional requirements without variation. This is where jigs and fixtures play a decisive role. They control part positioning, guide cutting tools, and stabilize workpieces so machining operations remain predictable and repeatable across large production volumes. Without properly designed solutions, even advanced CNC machines fail to deliver their full potential.

CNC shops today face tighter tolerances, shorter lead times, and increasing material complexity. As production scales, manual positioning and basic workholding methods introduce errors that compound over time. Purpose-built jigs and fixtures eliminate guesswork by defining exact locations and orientations before cutting begins. This approach improves productivity, reduces scrap, and ensures each part leaving the machine reflects the same quality standard.

Jigs and fixtures form the foundation of dimensional control in CNC machining. By locking a component into a predefined position, they remove variability caused by operator handling or inconsistent clamping. When a part is repeatedly located in the same reference position, tool paths remain consistent, allowing tight tolerances to be maintained across batches. This repeatability is especially critical in aerospace, automotive, and medical manufacturing where deviation is unacceptable.

Beyond dimensional accuracy, consistent fixturing also protects surface integrity. Stable workholding minimizes vibration and chatter, improving surface finish and extending tool life. Over time, this stability translates into lower tooling costs and fewer rejected parts.

One of the most overlooked advantages of jigs and fixtures tooling is setup efficiency. Instead of aligning each workpiece manually, operators load parts directly into predefined nests or locating pins. This reduces machine downtime and simplifies training requirements. Even less-experienced operators can achieve expert-level consistency when guided by a well-designed system.

Faster setups also allow manufacturers to respond quickly to production changes. Shorter changeover times mean CNC machines spend more hours cutting and fewer hours idle, directly improving profitability.

Effective jig and fixture design begins with understanding part geometry, machining sequence, and cutting forces. Designers must ensure that the workpiece is fully constrained without distortion. Locating points, clamps, and supports are positioned to counteract machining loads while maintaining accessibility for tools.

Material selection also plays a role. Hardened steels, aluminum alloys, and engineered polymers are chosen based on strength, wear resistance, and weight considerations. A balanced design delivers rigidity without unnecessary mass, ensuring long-term reliability.

Different CNC operations demand different approaches. Milling fixtures require strong lateral support to resist cutting forces, while turning fixtures focus on concentricity and balance. Drilling jigs guide tools directly, ensuring hole accuracy even at high speeds. Tailoring each design to its machining process ensures optimal performance and consistent output.

Ignoring process-specific requirements often leads to premature wear or part distortion. A thoughtful design aligned with the machining strategy avoids these issues from the start.

Modern products increasingly feature complex shapes and multi-axis machining requirements. Custom jigs and fixtures enable secure positioning of irregular parts that standard vises cannot hold. Multi-face fixtures allow several operations to be completed in a single setup, reducing handling and cumulative error.

These advanced solutions are particularly valuable in high-mix, low-volume production where flexibility is essential. Modular components can be reconfigured quickly to support different parts without full redesign.

As demand grows, scalability becomes a priority. Properly engineered fixtures ensure that increasing output does not compromise quality. Once validated, the same fixture design can be replicated across multiple machines, maintaining uniform standards across facilities.

Key benefits of scalable workholding systems include:

By standardizing workholding strategies, manufacturers create a stable foundation for growth.

Inconsistent workholding is a leading cause of scrap in CNC machining. Even minor shifts during cutting can result in out-of-tolerance parts. Well-designed jig and fixture design devices prevent movement, ensuring that each cut occurs exactly as programmed.

Reduced scrap directly impacts profitability. Less material waste, fewer re-machining operations, and lower inspection failures contribute to healthier margins and more reliable delivery schedules.

Efficiency is not only about speed. It is about predictable outcomes and reduced variability. Jigs and fixtures streamline workflows by simplifying setups, stabilizing processes, and supporting automation initiatives such as robotic loading.

Operational improvements achieved through optimized workholding include:

When these gains accumulate, the return on investment becomes clear.

As CNC shops adopt automation, jigs and fixtures evolve to support robotic handling and smart sensors. Fixtures designed with automation in mind include standardized interfaces and repeatable locating features that robots can engage reliably.

Sensor integration allows real-time monitoring of clamping force and part presence. This data-driven approach improves process control and reduces the risk of machining errors before they occur.

Off-the-shelf solutions rarely meet the demands of specialized manufacturing. Custom-designed systems tailored to specific parts and processes provide a competitive edge. By aligning workholding strategies with production goals, manufacturers achieve higher quality with lower long-term costs.

In an industry where precision defines reputation, investing in purpose-built jigs and fixtures is not an expense but a strategic decision that supports sustainable growth.

CNC machining excellence depends on more than advanced equipment and skilled operators. It relies on stable, accurate, and repeatable workholding solutions that support every cutting operation. From reducing setup time to enabling scalable production, jigs and fixtures remain essential tools in precision manufacturing. By prioritizing thoughtful design and application, manufacturers can achieve consistent quality, operational efficiency, and long-term competitiveness in an increasingly demanding market.